In today’s business environment, efficient production management is not just an advantage — it’s a necessity. From assembly delays to planning errors, any disruption can lead to financial losses and a decline in customer trust. That’s why many companies choose Odoo Manufacturing — an ERP module designed to optimize production workflows, reduce manual work, and bring more transparency to operations.

What is Odoo Manufacturing?

Odoo Manufacturing is a flexible module within the Odoo ERP system, built to plan, track, and control every stage of the manufacturing process. From creating Bills of Materials (BOMs) to managing work orders, quality control, warehouse integration, and even cost calculation — everything happens in one unified environment.

The Odoo Manufacturing (MRP) module is the central hub for managing all production processes. It allows you to plan, organize, execute, and monitor manufacturing orders—all from a single interface. Whether you run make-to-order, custom, or serial production, this module provides the tools to efficiently manage time, resources, and operations.

Who Is It For?

- Companies with serial or made-to-order production

- Businesses that need to manage complex BOM structures

- Factories requiring precise control of resources and time

- Manufacturers aiming to automate and optimize operations

How it works

Odoo Manufacturing combines powerful features with an intuitive interface to help you streamline and automate every stage of the production cycle. Below is a breakdown of the core components that make up the module — from managing orders and BOMs to configuring operations and routings.

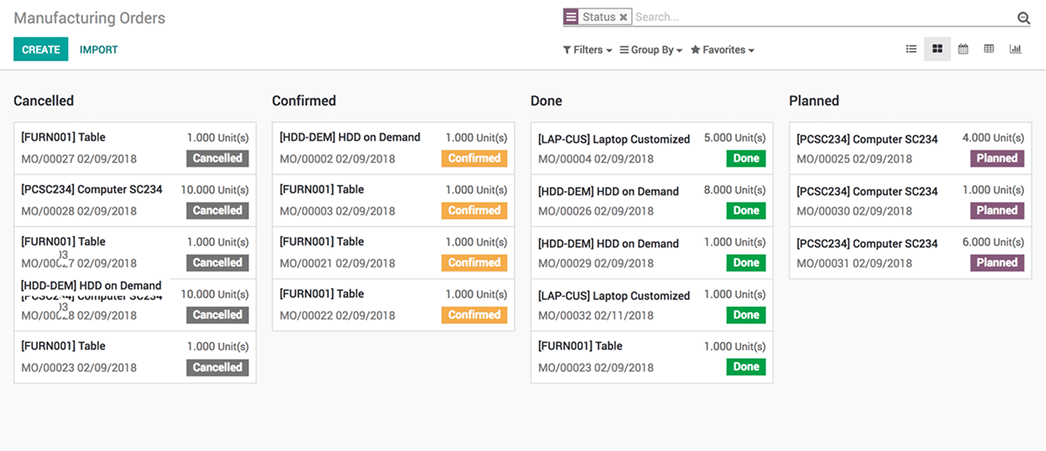

Manufacturing Orders (MOs)

- Create and process manufacturing orders manually or automatically (based on demand or forecast)

- Track the status of each order: Planned → In Progress → Done

- Split, merge, or duplicate orders as needed

Bill of Materials (BOM)

- Support for multi-level BOMs

- Alternative components, product variants, and substitutions

- Shared BOMs across multiple products

- Include materials, subassemblies, labor, and overheads

Routings & Operations

- Plan the sequence of operations for production steps

- Assign routings to BOMs or specific orders

- Define durations, required resources, and equipment

- Configure setup times and actual processing durations

Planning & Workload Management

Effective production planning requires more than just calendars and spreadsheets — it demands real-time insights, flexibility, and precision. Odoo equips manufacturers with the tools to anticipate demand, allocate resources wisely, and adapt quickly to change, helping teams stay in control even in complex or high-volume environments. Here's how Odoo helps streamline your planning and scheduling process:

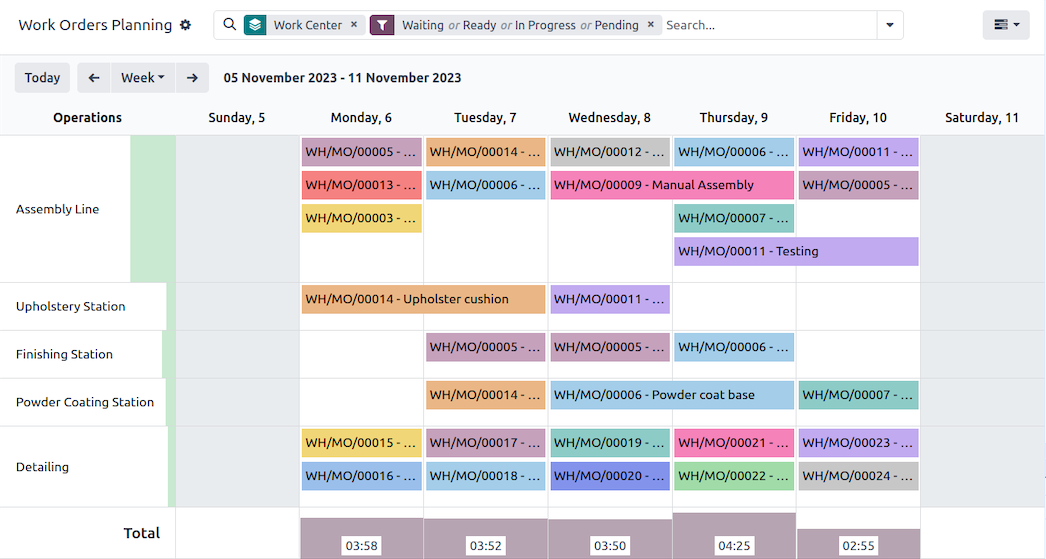

Visual Scheduler (Gantt)

- Build production schedules based on real-time data

- Drag-and-drop planning interface

- Detect bottlenecks or downtime across work centers

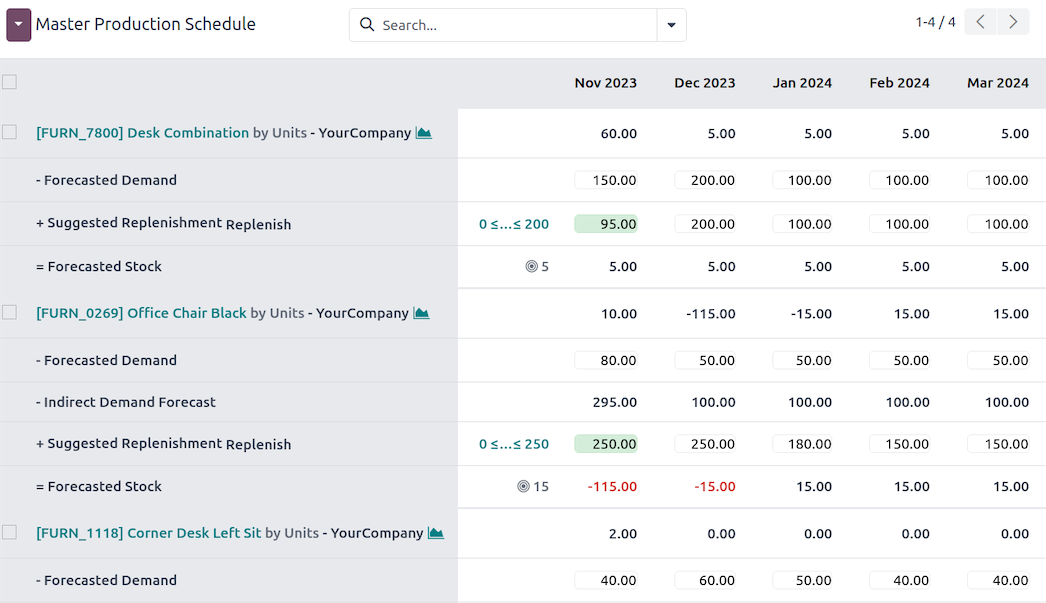

Automatic Scheduling

- Automatically generate orders based on stock levels and forecasts

- Account for capacity, work center efficiency (OEE), and priorities

- Ensure optimal load balancing across operations

Cost & Performance Management

To stay competitive, manufacturers need clear visibility into production costs and team performance. Odoo empowers businesses to monitor key financial and operational metrics in real time — helping reduce waste, improve efficiency, and make smarter decisions based on actual data rather than assumptions.

Cost Calculation

- Calculate product cost based on materials, labor, machine usage, and overheads

- Compare planned vs. actual costs per order

- Analyze profitability per product or production batch

Time Tracking

- Track operation time manually or with timers

- Compare actual execution time with planned durations

- Measure employee productivity and identify inefficiencies

Traceability & Execution Control

In manufacturing, precision and accountability are critical — not only for product quality but also for regulatory compliance and customer trust. Odoo provides full visibility into every step of the production process, while ensuring that operators follow standardized procedures with clarity and confidence.

Product Tracking

- Full traceability of serial and lot numbers

- View the complete movement history from raw material to delivery

- Meet quality, compliance, and audit requirements

Work Instructions & Worksheets

- Attach step-by-step guides and visuals for operators

- Embed PDFs, technical drawings, and images directly into orders

- Standardize execution to reduce errors

Learn more about the customization options of the Odoo Manufacturing module here.

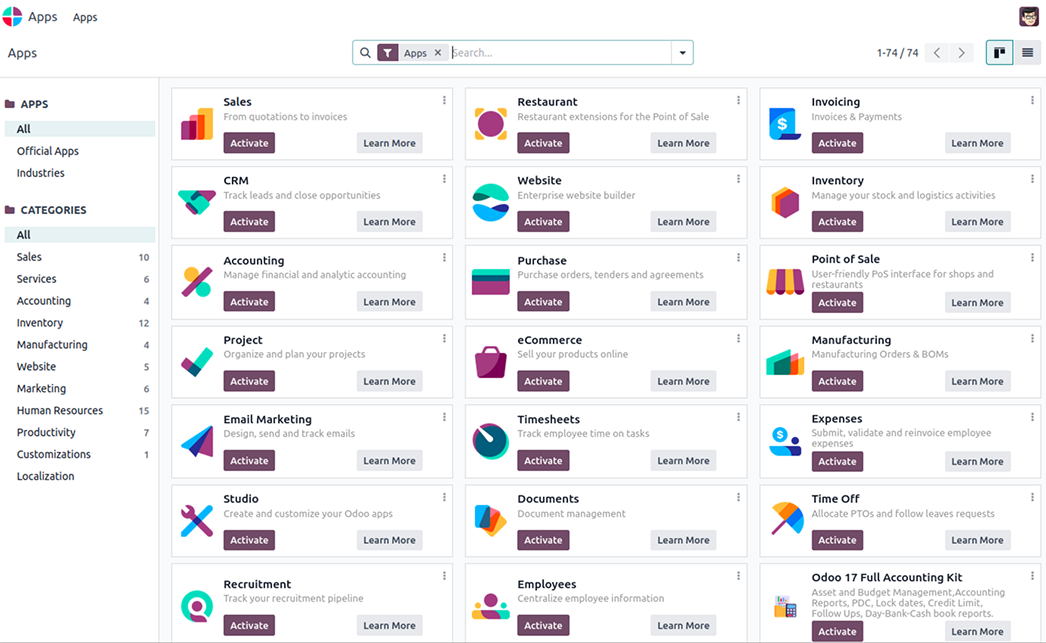

Odoo Manufacturing Is Just One Part of a Powerful ERP Ecosystem

The Odoo Manufacturing module is only one component of a comprehensive ERP system that covers all essential processes in a manufacturing business. Thanks to deeply integrated modules, you gain full control over your resources, equipment, personnel, and product quality — all within a single digital environment.

Here’s how it works:

Inventory

Manage all stock, logistics, and warehouse operations with maximum accuracy. The Inventory module automates receipts, deliveries, internal transfers, and storage workflows.

Key features:

- Multi-warehouse and multi-location management

- Batch and serial number tracking

- Barcode support (scanning and printing)

- Replenishment forecasting and automation

- Integration with shipping carriers (DHL, UPS, FedEx, etc.)

Purchase

Automate your procurement processes and efficiently manage supplier relationships. You can generate purchase orders manually or automatically (based on stock rules) and monitor vendor performance.

Functionality includes:

- Processing purchase requests (RFQs)

- Supplier price comparisons

- Agreements, tenders, and contracts

- Delivery deadline tracking and compliance control

- Full integration with Inventory and Manufacturing

Product Lifecycle Management (PLM)

Digitize product documentation and manage engineering changes in one place. PLM gives you clear version control and collaborative change management through ECOs (Engineering Change Orders).

Key features:

- Version comparison of Bills of Materials (BOM)

- Visual Kanban board for change approvals

- Linking products to documentation and routings

- Transparent change tracking with full audit history

Maintenance

Schedule preventive maintenance and avoid unexpected equipment downtime. The Maintenance module integrates with production operations and helps you manage equipment status in real time.

Key features:

- Preventive and corrective maintenance requests

- Calendar- and metric-based auto-scheduling

- Resource and technician assignment

- Downtime tracking, service cost analysis, and MTTR reporting (Mean Time To Repair)

Quality

Ensure compliance with quality standards at every production stage. The Quality module allows you to set control points, run checks, and document results.

Functionality includes:

- Quality control on incoming, in-process, and finished goods

- Checks with result logging and issue tracking

- Work instructions and documentation for staff

- Root cause analysis and corrective/preventive actions (CAPA)Reporting and dashboards for managers

Shop Floor

Gain real-time visibility into operations on the production line. Designed for operators and team leads, this module brings clarity to execution and coordination on the shop floor.

Main features:

- Intuitive touchscreen interface for task execution

- Real-time time tracking on operations

- Step-by-step digital work instructions

- Live production queue and order status

- Integration with barcode scanners, tablets, and industrial touchscreens

You can learn more about the Shop Floor module in our dedicated article.

IoT Box (Internet of Things)

Connect your hardware and sensors directly to Odoo.

The IoT Box lets you integrate devices like scales, label printers, barcode readers, and temperature sensors.

Capabilities:

- Supports USB, Bluetooth, Wi-Fi, HDMI, and other interfaces

- Real-time signal processing and event handling

- Full integration with MRP, Inventory, and Quality modules

How Businesses Implement Odoo Manufacturing in Practice

Manufacturers across various industries trust Solvve with their Odoo implementations. Explore our experience in setting up Odoo for production companies around the world — and see for yourself how seamlessly it can work for your business too.

Exxentric, a Swedish-based company, specializes in crafting cutting-edge equipment for strength training and rehabilitation. The Odoo system helps automate the company’s complex workflows and reduce manual operations across international offices. It standardizes and automates critical business tasks, improves efficiency, prepares the system for future growth, and accelerates operations through seamless third-party integrations.

Gansco is a Canadian company specializing in tableware and kitchenware manufacturing and sales, serving a diverse customer base worldwide. Thanks to Odoo, the company optimized warehouse processes with transparent reporting and connected over 25 marketplaces to the system. Additionally, the company received and fine-tuned sales, cargo shipping, and internal logistics modules, resulting in streamlined operations, efficient management, and high-quality service.

LedPax is a Canadian LED lighting manufacturer and distributor. With Odoo, the company modernized production and order tracking by replacing outdated tools. Custom modules ensured smooth coordination between warehouse, sales, and engineering, cut manual work, and brought all operations into one reliable system.

Conclusion

The true power of Odoo lies in seamless integration: all modules work together out-of-the-box, reducing manual tasks, speeding up order processing, and minimizing errors. You’re not just automating production — you’re building a unified digital system for managing your entire business.

Want to see how it works in action?

Book a live demo — we’ll show you how Odoo streamlines production from A to Z.