Mold Management for MRP by SOLVVE

Custom Odoo functionality for manufacturers of molded products.

A specialized module for manufacturers working with molds. Enables using a single mold across multiple machines, automatically plans production based on mold availability, and tracks wear and maintenance. Improves planning accuracy, production flexibility, and provides comprehensive mold utilization analytics.

Get in touch - we’ll walk you through.

How does it Work?

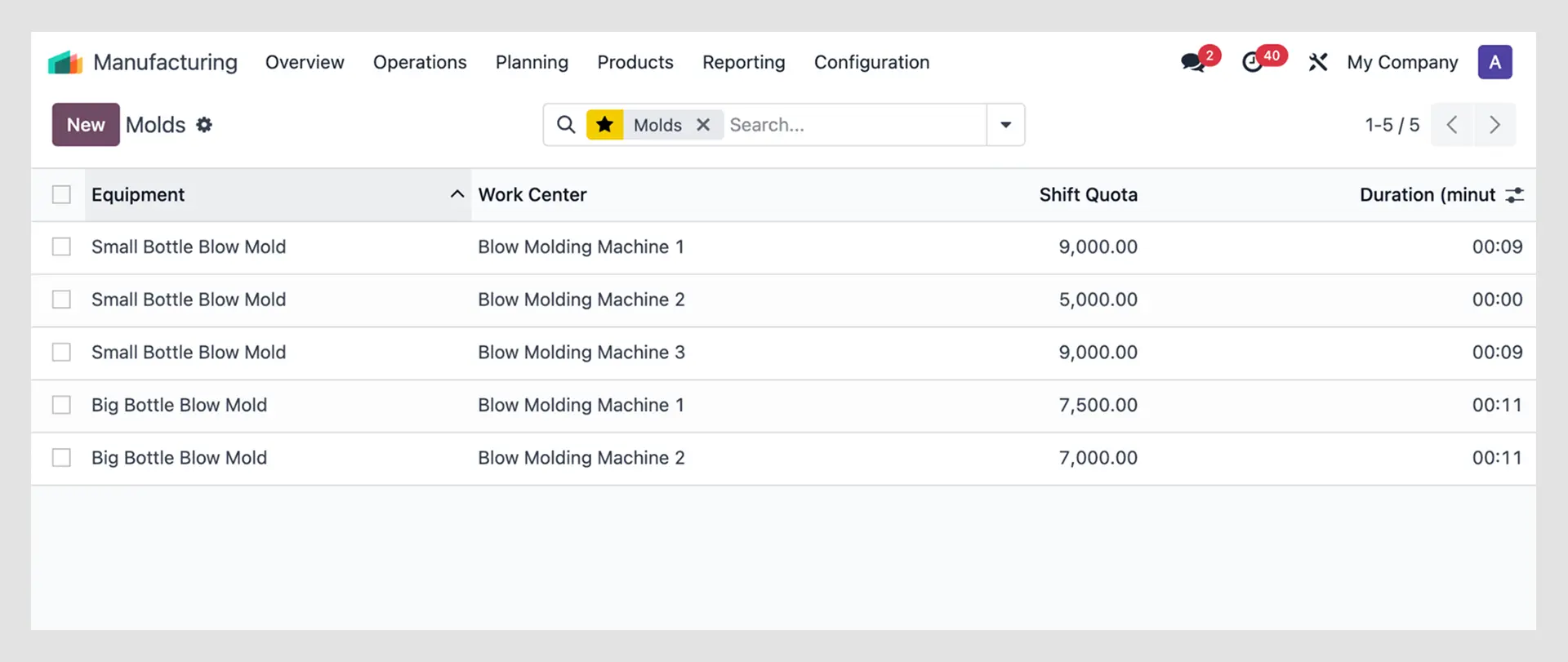

Mold assignment across multiple work centers

Setting cycle time for a specific products

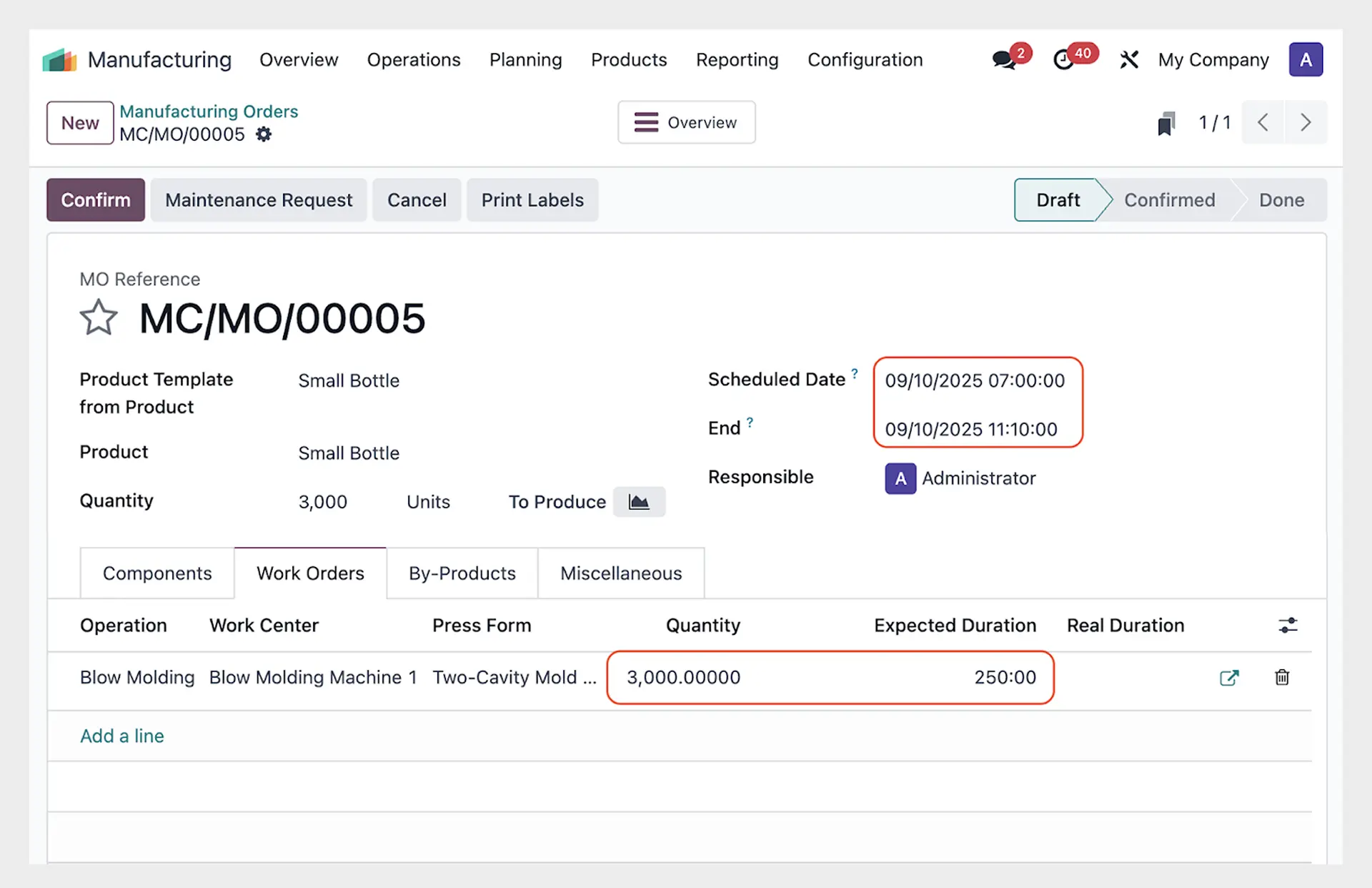

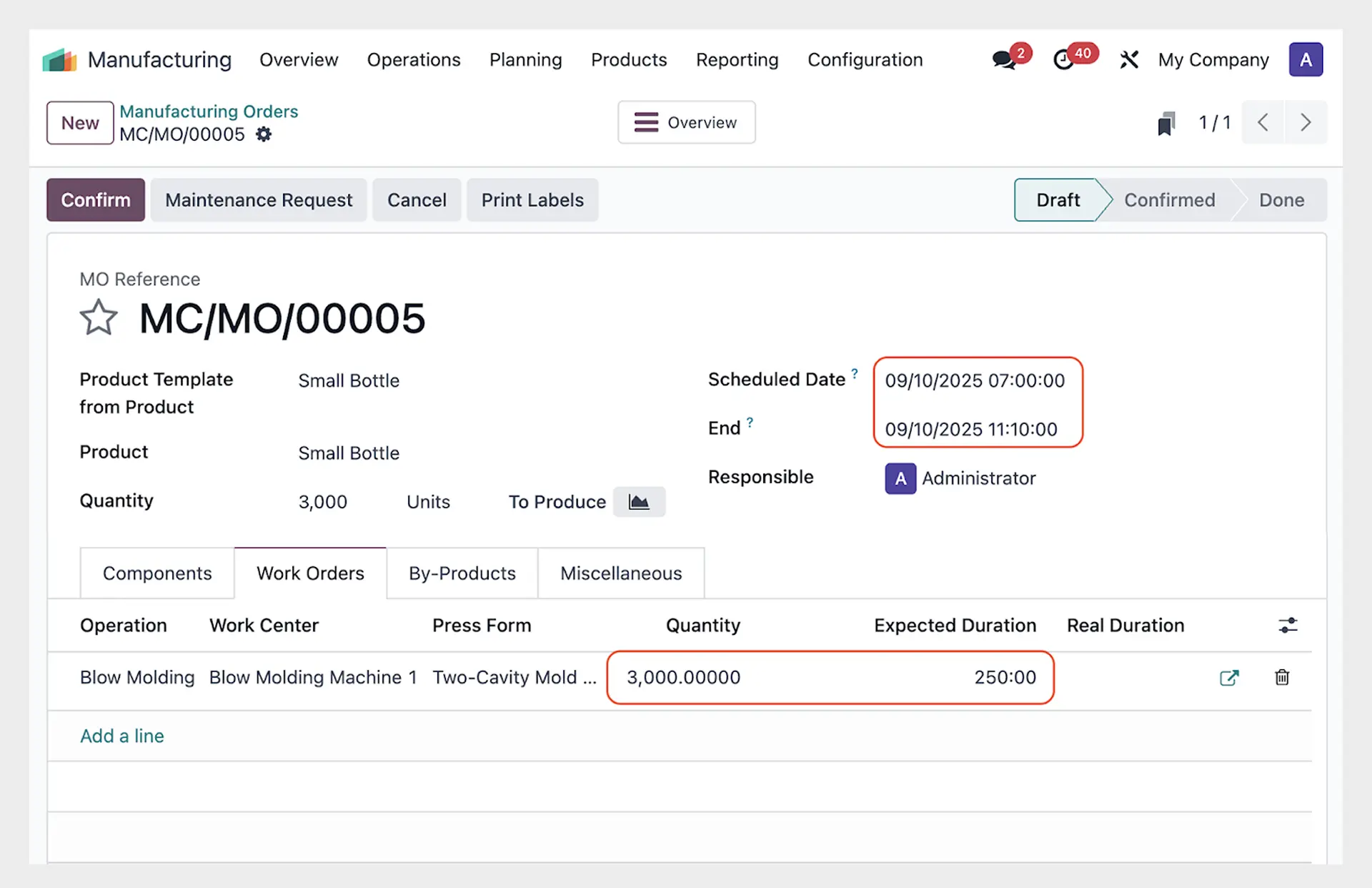

Automatic inclusion in the manufacturing order

Multiple molds for a single products

Technical solution for mold utilization and production efficiency

A powerful customization for manufacturers working with molds - integrating mobility, intelligent planning, and analytics into Odoo’s manufacturing workflow.

Unlock:

Mobility - a single mold can be used across different machines (e.g., plastic injection molding machines, stamping presses, extrusion lines)

Accurate time tracking - you can define how long it takes to produce a specific product on a specific mold

Automation - the system automatically selects the appropriate mold for a manufacturing order

Maintenance - tracks when a mold needs repair and how many cycles it has completed

Flexible Mold Assignment

Assign a single mold to multiple work centers - such as blow molding machines, injection molding machines, extrusion lines, milling equipment, stamping machines, or casting units - for dynamic production workflows.

Accurate Cycle Time Tracking

Define the cycle time per product and mold combination, reflecting real-world production differences and significantly improving planning precision.

Smart Automation

Link multiple molds to a product and have the correct mold automatically added to the Manufacturing Order - reducing manual entry and boosting accuracy.

Put your molds to work at full potential - try our Mold Management for MRP

Why Choose Mold Management Module?

Standard Odoo equipment functionality doesn't account for the unique needs of mold-based manufacturing. Our Mold Management module bridges this gap by enabling mold mobility across machines, precise cycle time tracking per mold-product combination, and automated mold assignment in production orders.

You get realistic production planning that considers both machine and mold availability, deeper insights into mold utilization and wear patterns, and seamless integration with maintenance workflows. This means fewer scheduling conflicts, better resource optimization, and data-driven decisions that directly impact your bottom line.

Built specifically for manufacturers working with injection molding, blow molding, stamping, casting, and extrusion - this module transforms Odoo from a generic ERP into a manufacturing system that truly understands your production process.

Business Benefits

Realistic Planning

The system accounts for both machine availability and mold availability - enabling production planning that aligns closely with reality.

Increased Flexibility

Increased Flexibility No more scheduling constraints - one mold can serve multiple machines, adapting to varied production needs.

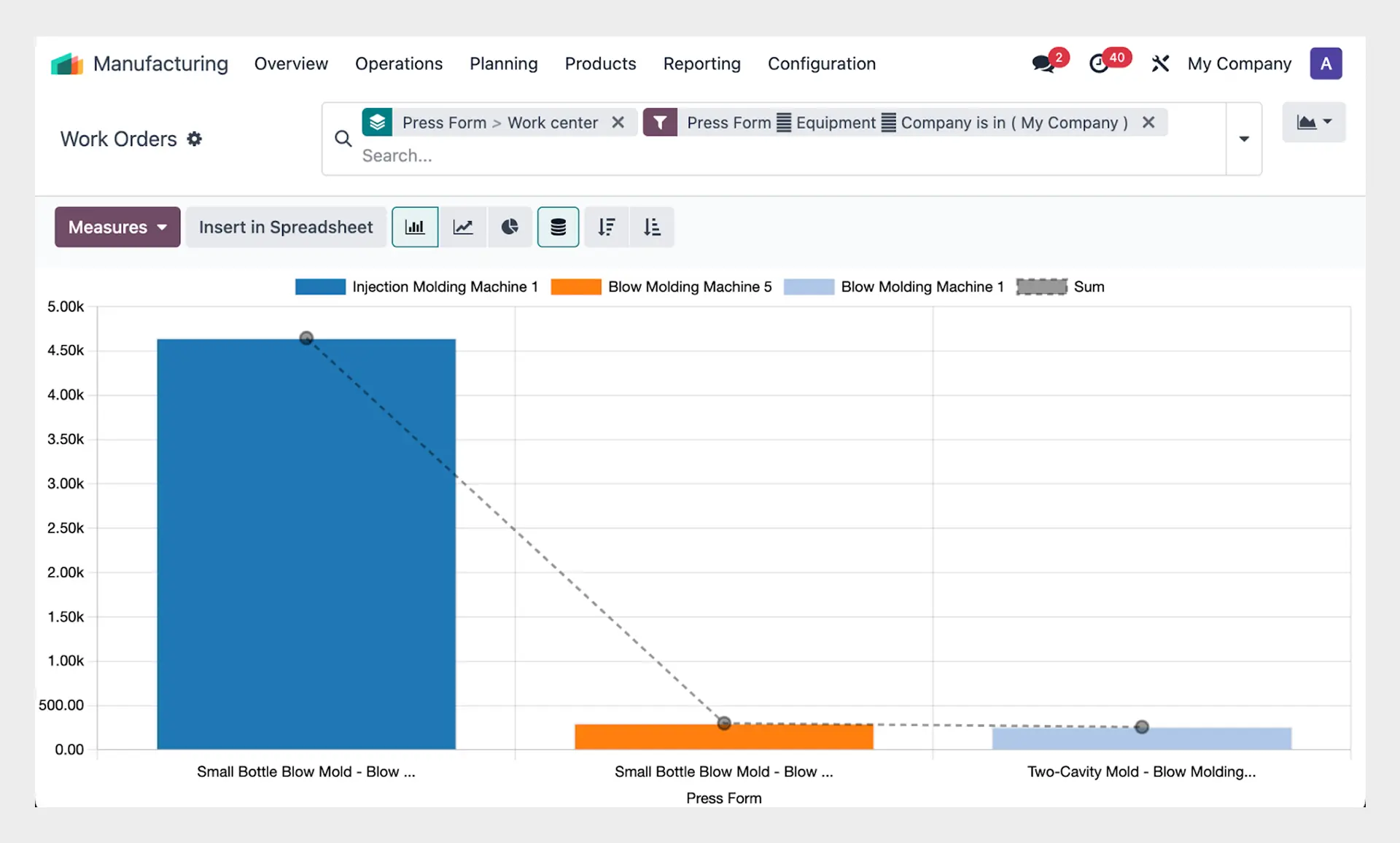

Enhanced Analytics

Gain deep insights into mold utilization, workloads, and production efficiency - providing groundwork for cost control, quality assurance, and wear forecasting.

Advanced Capabilities for Your Business

Maintenance Integration

Seamlessly integrates with Odoo’s Maintenance module to support scheduled repairs and preventive maintenance of molds.

Lifecycle Management

Track mold usage via cycle counts, monitor transfer history across machines, and forecast end-of-life timelines for proactive replacement.

From planning to analytics -take your manufacturing to the next level

Request a demo and see Mold Management for MRP in action